SDI for Corn Production: A Ten Year Summary of Research

FREDDIE R. LAMM1 and TODD P. TROOIEN2

1 Kansas State University, 105 Experiment Farm Road, Colby, Kansas USA. 67701-1697

2 South Dakota State University, Box 2120, Brookings, South Dakota USA. 57007-1496

ABSTRACT

Kansas State University initiated studies in 1989 to develop the methodology for successful application of subsurface drip irrigation (SDI) for corn production on the deep silt loam soils of the Central Great Plains, USA. Irrigation water use for corn can be reduced from 35 to 55% when using SDI compared to more traditional forms of irrigation in the region. Irrigation frequency has not been a critical issue when SDI is used for corn production onthe deep silt loam soils of the region. A dripline spacing of 1.5 m has been found to be most economical for corn grown in 0.76 m spaced rows. Nitrogen fertigation was a very effective management tool with SDI, helping to maximize corn grain yield yields, whileobtaining high efficiencies of nitrogen and water use. The research SDI systems have been utilized since 1989 without replacement or major degradation. SDI systems lasting 10-20 years are cost competitive for corn production with the more traditional forms of irrigation in the Great Plains for certain field sizes and water constraints.

1. INTRODUCTION

SDI typically has not been used in the Great Plains (Central USA) for field corn (Zea mays) production because of high initial costs and because of the uncertainty about SDI system life. However, with increasing concerns about water conservation and water quality protection, irrigators are looking for more efficient irrigation systems. Kansas State University (KSU) began a research program in 1989 to develop a management system for utilizing SDI for corn production. This paper will describe the results from several research studies including water use (timing, frequency, and amounts); drainage and percolation; nitrogen fertilization; dripline spacing; system uniformity; system life; and economics. Expansion of SDI in the Great Plains will be affected by the consistent management requirements needed to ensure long system life, system design and cost, crop prices, and physical and institutional constraints on water availability. This body of research has determined many of the technical management issues and the adoption of SDI is increasing.

To whom all correspondence should be addressed:

Tel +01 785 462 6281; Fax +01 785 462 2315; e-mail:flamm@ksu.edu

2. PROCEDURES

This report summarizes several studies conducted at the KSU Northwest and Southwest Research-Extension Centers at Colby and Garden City, Kansas, respectively. A complete discussion of all the procedures employed lies beyond the scope of this paper. For further information about the procedures for a particular study, the reader is referred to the cited reference. The following general procedures apply to all studies unless otherwise stated.

The study sites are located on deep, well-drained, loessial, silt loam soils. These medium-textured soils, typical of many western Kansas areas, will hold approximately 480 mm of plant-available soil water in the 2.4 m profile at field capacity. The study areas are nearly level with land slopes less than 0.5% at Colby and 0.1% at Garden City. The continental climate can be described as semi-arid, with an average annual precipitation of 460 mm. Daily climatic data used in the studies were obtained from weather stations operated on each of the Centers.

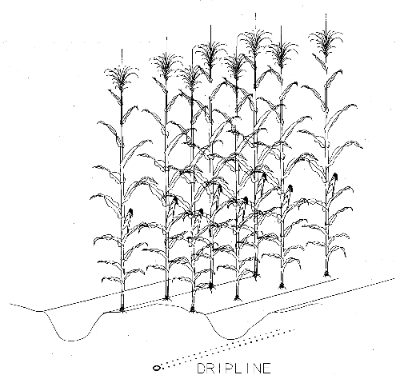

The studies utilized SDI systems installed in 1989-90 (Lamm et al. 1990). The dual-chamber drip tape was installed at a depth of approximately 40-45 cm with a 1.5 m spacing between dripline laterals. Emitter spacing was 30 cm and the dripline flowrate was 1.86 l/hr-m. The corn was planted so that each dripline lateral was centered between two corn rows (Figure 1).

A ridge-till system was used in corn production with two corn rows, 76 cm apart on a 1.5 m bed. Flat planting was used for the dripline spacing studies conducted at both locations. Matching bed spacing to dripline spacing was impractical with the available tillage and harvesting equipment. Additionally, at Garden City, the corn rows were planted perpendicular to the driplines in the dripline spacing study.The corn was grown with the conventional production practices for each location. Tractor traffic was confined to the furrows.

Irrigation was scheduled for the studies using a water budget to calculate the root zone depletion with precipitation and irrigation water amounts as deposits and calculated daily water use by corn as a withdrawal. reatments were irrigated to replace 100% of their calculated root-zone depletion, when the depletion was within the range of 20 to 35 mm. Soil wateramounts were monitored with a neutron probe in 30-cm increments to a depth of 2.4 m approximately once a week during each crop season.

Figure 1. Physical arrangement of the subsurface dripline in relation to the corn rows.

3. RESULTS AND DISCUSSION

3.1 Irrigation and Water Use

3.1.1 Water requirement of subsurface drip-irrigated corn. Research studies were conducted at Colby, Kansas from 1989-1991 to determine the water requirement of subsurface drip-irrigated corn. Irrigation treatments designed to replace 25, 50, 75, 100, and 125% of evapotranspiration were compared to a control treatment with no in-season irrigation. Corn yields were highly linearly related to calculated crop water use (Figure 2); 0.048 Mg/ha of grain was obtained for each mm of water used above a threshold of 325 mm (Lamm et al. 1995a). Careful management of SDI systems reduced net irrigation needs by nearly 25%, while still maintaining top yields of 12.5 Mg/ha. The 25% reduction in irrigation needs translated into 35-55% savings when compared to sprinkler and furrow irrigation systems that typically operate at 85 and 65% application efficiencies, respectively. Indeed, these savings are being confirmed by producers' anecdotal reports of 50% irrigation savings with SDI compared to furrow irrigation. The relationship between corn yields and irrigation was nonlinear (Figure 2) primarily because of greater drainage for the heavier irrigation amounts (Figure 3). The 25% reduction in net irrigation needs was associated primarily with the reduction of in-season drainage, a nonbeneficial component of the water balance.

Figure 2. Corn grain yield as related to irrigation and calculated evapotranspiration (AET) in a SDI study, Colby, Kansas, USA, 1989-91.

Figure 3. Calculated evapotranspiration (AET) and seasonal drainage as related to irrigation treatment in a SDI study, Colby, Kansas, USA, 1989-1991.

3.1.2 Frequency of subsurface drip irrigation. Typically, a smaller volume of soil is wetted with SDI than by other types of irrigation systems, and as a result, crop rooting may be limited. Crops may benefit from frequent irrigation under this condition. However, frequencies of 1, 3, 5, or 7 days produced similar high corn yields (11.9 to 12.5 Mg/ha). Higher irrigation water use efficiencies were obtained with the longer 7-day frequency because of better storage of in-season precipitation and because of reduction in drainage below the rootzone (Caldwell et al. 1994). The results indicate little need to perform frequent subsurface drip irrigation events for fully irrigated corn on the deep silt loam soils of western Kansas. Some evidence indicates that daily irrigation events may be beneficial under deficit irrigation conditions or in cases where fertigation is practiced. Several of the more advanced research studies currently underway at Kansas State University routinely utilize daily irrigation events.

3.2 Dripline spacing

Increasing the spacing of dripline laterals would be one of the most important factors in reducing the high investment costs of SDI. Soil type, dripline installation depth, crop type and the reliability and amount of in-season precipitation probably are the major factors that determine the maximum dripline spacing. Research studies at Colby and Garden City, Kansas have determined that driplines spaced 1.5 m inches apart are most economical for corn grown in rows spaced 0.76 m apart, at least on the deep silt loam soils of this semi-arid region (Lamm et al. 1997a, Manges et al. 1995). Wider dripline spacings of 2.1 or 3 m resulted in decreased yields and excessive deep percolation. (Lamm et al. 1997a, Lamm et al. 1995b, Darusman et al. 1997) but may have some application in regions having higher precipitation (Powell and Wright, 1993).

3.3 Nitrogen fertilization

Because SDI systems have a high degree of uniformity when designed properly and can apply small amounts of irrigation frequently, they provide excellent opportunities to better manage nitrogen fertilization. Injecting small amounts of nitrogen solution into the irrigation water can spoon-feed the crop, while minimizing the pool of nitrogen in the soil that could be available for percolation into the groundwater.

In a study conducted at Colby, Kansas, no differences occurred in corn yields between preplant surface-applied nitrogen and nitrogen injected into the driplines throughout the season. However, residual soil-nitrogen levels were higher where nitrogen was injected, suggesting that similar corn yields might be obtained at lower amounts of injected nitrogen (Lamm and Manges, 1991). In a subsequent study, a Best Management Practice (BMP) was developed for in-season nitrogen fertigation of corn (Lamm et al. 1997b). Residual ammonium- and nitrate-nitrogen levels in the soil profile, corn yields, apparent nitrogen uptake (ANU) and water use efficiency (WUE) were utilized as criteria for evaluating six different nitrogen fertigation rates: 0, 90, 135, 180, 225, and 275 kg/ha. The resultant BMP was a nitrogen fertigation level of 180 kg/ha; other nonfertigation applications brought the total applied nitrogen to approximately 215 kg/ha. The BMP also states that irrigation is to be scheduled and limited to replace approximately 75% of ET which will help limit leaching without reducing corn yield. Corn yield, ANU, and WUE all plateaued at the same level of total applied nitrogen, which corresponded to the 180 kg/ha nitrogen fertigation rate (Figure 4). Average yields for the 180 kg/ha nitrogen fertigation rate were 13.4 Mg/ha. The ratio of corn yield to ANU for the 180 kg/ha nitrogen fertigation rate was a high 53:1. These results emphasize that high-yielding corn production also can be efficient in nutrient and water use.

Figure 4. Average (1994-96) corn yield, apparent nitrogen uptake in the above-ground biomass, and water use efficiency as related to the total applied nitrogen (preseason amount, starter fertilizer, fertigation, and the naturally occurring N in the irrigation water). Total applied nitrogen exceeded fertigation-applied nitrogen by 35 kg/ha.

3.4 System Life and Economics

Typically, SDI has much higher investment costs compared to other pressurized irrigation systems such as full-sized, 50 ha, center pivot sprinklers. However, there are realistic scenarios where SDI can compete directly with center pivot sprinklers for corn production in the Central Great Plains (O'Brien et al. 1998). One example is with decreasing field size, because the ratio of center pivot sprinkler costs to irrigated acres increases rapidly. (Figure 5).

Figure 5. Net returns advantage of SDI over center pivot (CP) sprinkler irrigation as affected by system size and SDI life. Assumptions are that CP system life is 20 years, average corn yield is 11.9 Mg/ha, and corn grain price is US$98.42/Mg.

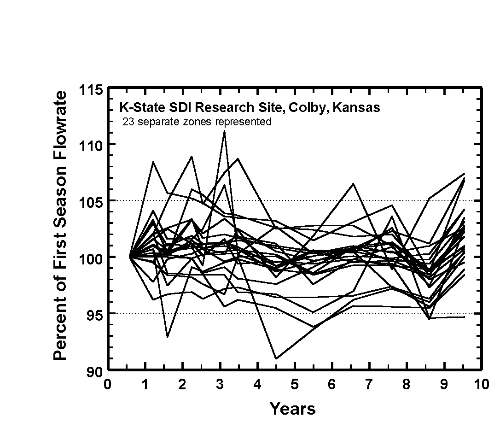

The life of a SDI system must be at least 10-15 years to reasonably approach economic competitiveness with full-sized, 50 ha, center pivot sprinkler systems that typically last 20 years (Figure 5). Using careful and consistent maintenance, a 15-20 year SDI system life appears obtainable when high quality water from the Ogallala aquifer is used. The system performance in KSU SDI research plots has been monitored annually since 1989. Pressures and flowrates for each zone have been measured at the end of each irrigation season to allow comparisons of long-term flowrate degradation. The time series representation of a study area (23 separate zones) at Colby, Kansas indicates that in the vast majority of cases, flowrates did not vary by more than +/- 3% over the 10 seasons (Figure 6). In fact, flowrates at the close of 1998 were predominately 0-3% higher than those in 1989. This study area has received shock chlorination approximately 2-3 times each season, but has not received any other chemical amendments such as acid or fertilizer. The water source at this site has a total dissolved solids (TDS) of 279, hardness of 189.1, and pH of 7.8. Traditional classifications would identify this water source as a moderate chemical plugging hazard.It is possible that the depth of the SDI system (0.40-0.45 m) may have reduced the chemical plugging hazards because of lower temperature fluctuations and negligible evaporation directly from the dripline.

Figure 6.Variation in zone flowrates for 23 separate zones during the 10-year period from 1989 to 1998 at KSU SDI research site, Colby, Kansas.

4. Concluding Statements

Research progress has been steady since 1989. Irrigators are watching the results of KSU closely. Some irrigators have begun to experiment with the technology, and most appear happy with the results they are obtaining. The authors hope KSU's development of a knowledge base in advance of the irrigator adoption phase can minimize the misapplication of SDI technology and overall system failures. Economics of the typical Great Plains row crops will not allow frequent system replacement or major renovations. Irrigators must carefully monitor and maintain the SDI system to assure a long system life.

Continued or new areas of research are concentrating on optimizing allocations of water, seed, and nutrients, utilizing livestock wastewater, developing preliminary information about SDI use with other crops besides corn, water and chemical application uniformity, and finally system design characteristics and economics with a view towards system longevity.

5. REFERENCES

Caldwell, D. S., W. E. Spurgeon and H. L. Manges. 1994. Frequency of irrigation for subsurface drip-irrigated corn.Trans. ASAE, 37(4):1099-1103.

Darusman, A. H. Khan, L. R. Stone, and F. R. Lamm. 1997. Water flux below the root zone vs. drip-line spacing in drip-irrigated corn. Soil Sci Soc. J. 61:1755-1760.

Lamm, F. R., L. R. Stone, H. L. Manges, and D. M. O'Brien. 1997a. Optimum lateral spacing for subsurface drip-irrigated corn. Trans. ASAE, 40(4)1021-1027.

Lamm, F. R., A. J. Schlegel, and G. A. Clark. 1997b. Nitrogen fertigation for corn using SDI: A BMP. Presented at the int'l meeting of the ASAE, Minneapolis, MN, August 10-14, 1997. Paper No. 972174 from ASAE, St. Joseph MI, USA. 17 pp.

Lamm, F. R., H. L. Manges, L. R. Stone, A. H. Khan, and D. H. Rogers. 1995a. Water requirement of subsurface drip-irrigated corn in northwest Kansas. Trans. ASAE, 38(2)441-448.

Lamm, F. R., W. E. Spurgeon, D. H. Rogers, and H. L. Manges. 1995b. Corn production using subsurface drip irrigation. In Proceedings of the Fifth International Microirrigation Congress, Orlando, Florida, April 2-6, 1995. pp 388-394. ASAE, St. Joseph, MI, USA. 978 pp.

Lamm, F. R., and H. L. Manges. 1991. Nitrogen fertilization for drip-irrigated corn in northwest Kansas. Presented at the int'l winter meeting of the ASAE, Chicago, Illinois, December 17-20, 1991. Paper No. 912596 from ASAE, St. Joseph MI, USA. 17 pp.

Lamm, F. R., H. L. Manges, D. H. Rogers, W. E. Spurgeon, and M. H. Farmer. 1990. Design and installation of a drip irrigation system for research purposes. Presented at the int'l winter meeting of the ASAE, Chicago, IL, Dec. 18-21, 1990. Paper no. 902530 from ASAE, St. Joseph, MI., USA. 21 pp.

Manges, H. L., W. E. Spurgeon, Z. M. Huang, and D. J. Tomsicek 1995. Subsurface dripline spacing and plant population for corn production. In Proceedings of the Fifth International Microirrigation Congress, Orlando, Florida, April 2-6, 1995. pp 388-394. ASAE, St. Joseph, MI, USA. 978 pp.

O'Brien, D. M., D. H. Rogers, F. R. Lamm, and G. A. Clark. 1998. An economic comparison of subsurface drip and center pivot sprinkler irrigation systems. Applied Engr in Ag., 14(4)391-398.

Powell, N. L. and F. S. Wright. 1993. Grain yield of subsurface microirrigated corn as affected by irrigation line spacing. Agron. J. 85:1164-1170.

This paper was first presented at the Micro 2000, the sixth international microirrigation congress, Capetown, South Africa, October 22-27, 2000.

Contribution No. 00-282-A from the Kansas Agricultural Experiment Station, Manhattan, Kansas, USA.