SDI Research in Kansas After 10 Years

Freddie R. Lamm, Research Irrigation Engineer

Todd P. Trooien, Research Irrigation Engineer

Northwest and Southwest Research-Extension Centers

Colby and Garden City, Kansas

Kansas State University

BRIEF HISTORY

In the summer of 1988, K-State Research and Extension issued an in-house request for proposals for new directions in research activity. A proposal entitled Sustaining Irrigated Agriculture in Kansas with Drip Irrigation was submitted by irrigation engineers Freddie Lamm, Harry Manges and Dan Rogers and agricultural economist Mark Nelson. This project led by principal investigator Freddie Lamm, Northwest Research-Extension Center (NWREC), Colby, was funded for the total sum of $89,260. This project financed the initial development of the NWREC SDI system that was expressly designed for research. In March of 1989, the first driplines were installed on a 3 acre study site which has 23 separately controlled plots. This site has been in continuous use in SDI corn production since that time, being initially used for a 3-year study of SDI water requirements for corn. In addition, it is considered to be a benchmark area that is also being monitored annually for system performance to determine SDI longevity. In the summer of 1989, an additional 3 acres was developed to determine the optimum dripline spacing for corn production. A small dripline spacing study site was also developed at the Southwest Research-Extension Center (SWREC) at Garden City in the spring of 1989.

In the summer of 1989, further funding was obtained through a special grant from the US Department of Agriculture (USDA). This funding led to expansion of the NWREC SDI research site to a total of 13 acres and 121 different research plots. This same funding provided for the 10 acre SDI research site at Holcomb, Kansas administered by the SWREC. By June of 1990, K-State Research and Extension had established 25 acres of SDI research facilities and nearly 220 separately controlled plot areas.

Over the course of the past 10 years, additional significant funding has been obtained to conduct SDI research from the USDA, the Kansas Water Resources Research Institute, special funding from the Kansas legislature, the Kansas Corn Commission, Pioneer Hi-Bred Inc., and the Mazzei Injector Corporation. Funding provided by the Kansas legislature through the Western Kansas Irrigation Research Project (WKIRP) allowed for the expansion of the NWREC site by an additional 5.5 acres and 46 additional research plots in 1999. The NWREC SDI research site comprising 18.5 acres and 167 different research plots is the largest facility devoted expressly to small-plot row crop research in the Great Plains and is probably one of the largest such facilities in the world.

Since its beginning in 1989, K-State SDI research has had three purposes: 1) to enhance water conservation; 2) to protect water quality, and 3) to develop appropriate SDI technologies for Great Plains conditions.

Figure 1. Growth of microirrigation in Kansas from 1989 to 1998.

The use of SDI and other forms of microirrigation in Kansas is not large at this point in time. Only about 9,500 acres of the approximately 3 million irrigated acres in Kansas utilized microirrigation in 1998 (Figure 1). In 1989, when K-State initiated the SDI research, there were only about 2,500 microirrigated acres. This technology, which is clearly in its "infancy" in Kansas, has averaged growing 1320 acres/year.

SUMMARY OF RESEARCH ACTIVITIES

Twenty two research and extension projects have been conducted with SDI at Kansas State University since 1989 (Table 1). Some of these studies have been fully completed and published, while others are in various stages of completion. The vast majority of the studies have been conducted with field corn because it is the primary irrigated crop in the Central Great Plains. Although field corn has a relatively high water use efficiency, it generally requires a large amount of irrigation because of its long growing season and its sensitivity to water stress over a great portion of the growing period. Of the typical commodity-type field crops grown in the Central Great Plains, only alfalfa and similar forages would require more irrigation than field corn. Any significant effort to reduce the overdraft of the Ogallala aquifer, the primary water source in the Central Great Plains, must address the issue of irrigation water use by field corn.

The research and extension projects fall under at least one of the three purposes of water conservation, water quality protection, and SDI technology development and adaptation. Although there is some overlap of the three purposes among the projects, an approximately even number of projects have been devoted to each purpose (Table 1). During the early development years, K-State had projects devoted to all three purposes. Even now, K-State has studies devoted to all three purposes. Some of today's projects could be characterized as advanced technologies, perhaps fine-tuning techniques for successful use of SDI, while others are answering basic questions that were not deemed as high a priority in the earlier years.

A complete summarization of all the research and extension projects lies beyond the scope of this paper, but it may be worthwhile to review some projects that indicate the progress that has been made.

Research studies were conducted at Colby and Garden City, Kansas from 1989-1991 to determine the water requirement of subsurface drip-irrigated corn. Careful management of SDI systems reduced net irrigation needs by nearly 25%, while still maintaining top yields of 200 bu/a. The 25% reduction in irrigation needs translates into 35-55% savings when compared to sprinkler and furrow irrigation systems which typically are operating at 85 and 65% application efficiency. SDI technology can make significant improvements in water use efficiency through better management of the water balance components. The 25% reduction in net irrigation needs is primarily associated with the reduction in in-season drainage, a non-beneficial component of the water balance.

Typically, a smaller volume of soil is wetted with SDI as compared to other types of irrigation systems and as a result, crop rooting may be limited. Crops may benefit from frequent irrigation under this condition. However, high frequency SDI has not been a critical management technique for corn production on the deep silt loam soils of western Kansas as long as full irrigation is practiced. Frequencies of 1, 3, 5 or 7 days produced similar high corn yields (190-200 bu/acre). There is some evidence that daily irrigation events may be beneficial under deficit irrigation conditions or in cases where fertigation is practiced. Several of the more advanced research studies currently underway at Kansas State University routinely utilize daily irrigation events.

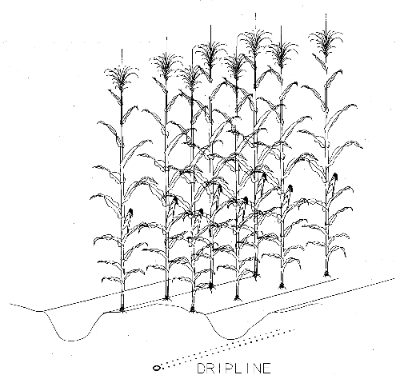

Increasing the spacing of dripline laterals would be one of the most important factors in reducing the high investment costs of SDI. Soil type, dripline installation depth, crop type and the reliability and amount of in-season precipitation are major factors that determine the maximum dripline spacing. Research studies at Colby and Garden City, Kansas have determined that driplines spaced 60 inches apart are most economical for corn grown in rows spaced 30 inches apart at least on the deep silt loam soils of the region. When subsurface driplines are centered between alternate pairs of corn rows, each corn row is within 15 inches of the nearest dripline (Figure 2.)

Table 1. SDI research studies conducted at Kansas State University and their status as of October 1, 1999.

| Research Study Title or Description of Study Topic | Project Status | Documentation Status |

| Water requirement of field corn using SDI | Completed 1991 | 2 Journal publications |

| Optimum dripline spacing for field corn | Completed 1991 | 2 Journal publications |

| Pre-plant vs. nitrogen fertigation for field corn using SDI | Completed 1991 | ASAE Meeting presentation |

| Zone length for SDI in Western Kansas | Completed 1991 | Regional ASAE Meeting presentation |

| Frequency of SDI for corn | Completed 1991 | Journal publication |

| Aeration with SDI | Completed 1995 | Brief project summary |

| Phosphorous and potassium fertigation for corn | Completed 1998 | Analysis of data in progress |

| Optimum plant population and irrigation capacity for corn | In progress since 1996 | Analysis of data in progress |

| Long-term performance of SDI | In progress since 1989 | Some results reported in this paper |

| Minimizing stress with high frequency SDI | Completed in 1997 | Analysis of data in progress |

| BMPs for nitrogen fertigation of corn using SDI | Completed in 1997, new study in 1997 | IA and ASAE Meeting presentations |

| Narrow row corn to optimize dripline spacing | Completed in 1995 | KWRRI Report |

| Economics of SDI for corn production | In progress since 1994 | Journal and extension publications |

| Effect of dripline spacing on watermelon | In progress since 1997 | Analysis of data in progress |

| Criteria for terminating the corn irrigation season | Initiated in 1999 | No results to report as of this date |

| Optimum dripline depth for corn using SDI | Initiated in 1999 | No results to report as of this date |

| Applying livestock wastewater with SDI | In progress since 1998 | IA and K-State Meeting presentations |

| Demonstration of SDI use on alfalfa | In progress since 1998 | Analysis of data in progress |

| Uniformity of irrigation and chemical application | In progress since 1997 | 2 ASAE Meeting presentations |

| Winter application with SDI | In progress since 1998 | Analysis of data in progress |

| Use of SDI on wheat and soybean | In progress since 1998 | Analysis of data in progress |

| Effect of early season water stress on corn using SDI | Initiated in 1999 | No results to report as of this date |

Figure 2. Physical arrangement of the subsurface dripline in relation to the corn rows.

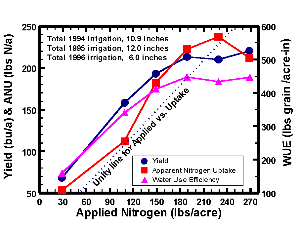

A four year study was conducted on the deep silt loam soils in western Kansas to develop a Best Management Practice (BMP) for nitrogen fertigation for corn using SDI. Residual ammonium- and nitrate-nitrogen levels in the soil profile, corn yields, apparent nitrogen uptake (ANU) and water use efficiency (WUE) were utilized as criteria for evaluating six different nitrogen fertigation rates, 0, 80, 120, 160, 200, and 240 lbs/acre. The BMP was a nitrogen fertigation level of 160 lbs/acre with the total applied nitrogen including other non-fertigation applications of approximately 190 lbs/acre. The BMP also states that irrigation is to be scheduled and limited to replace approximately 75% of ET. Corn yield, ANU, and WUE all plateaued at the same level of total applied nitrogen which corresponded to the 160 lbs/acre nitrogen fertigation rate (Figure 3). Average yields for the 160 lbs/acre nitrogen fertigation rate was 213 bu/acre. Corn yield to ANU ratio for the 160 lbs/acre nitrogen fertigation rate was a high 53:1. The results emphasize that high-yielding corn production also can be efficient in nutrient and water use.

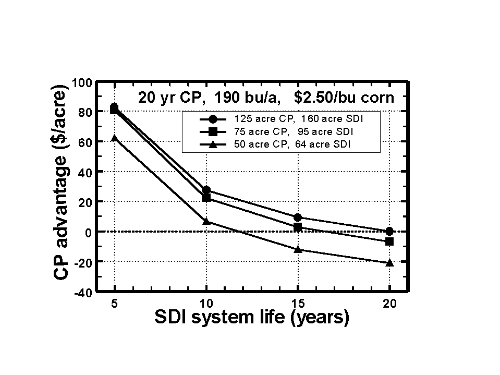

SDI has not been typically used for row crop production in the Central Great Plains. Typically, SDI has much higher investment costs as compared to other pressurized irrigation systems such as full size center pivot sprinklers. However, there are realistic scenarios where SDI can directly compete with center pivot sprinklers for corn production in the Central Great Plains. As field size decreases, SDI can more directly compete with center pivot sprinklers because of increasing higher ratio of center pivot sprinkler costs to irrigated acres (Figure 4).

Figure 3. Average (1994-96) corn yield, apparent nitrogen uptake in the above-ground biomass, and water use efficiency as related to the total applied nitrogen (preseason amount, starter fertilizer, fertigation, and the naturally occurring N in the irrigation water). Total applied nitrogen exceeded fertigation applied nitrogen by 30 lb/acre.

Figure 4. Annual advantage of center pivot sprinkler irrigation as related to SDI system life for various field sizes for a 20 year center pivot life when corn yield and price are 190 bushels/acre and $2.50/bushel. Adapted from K-State Extension MF-2242.

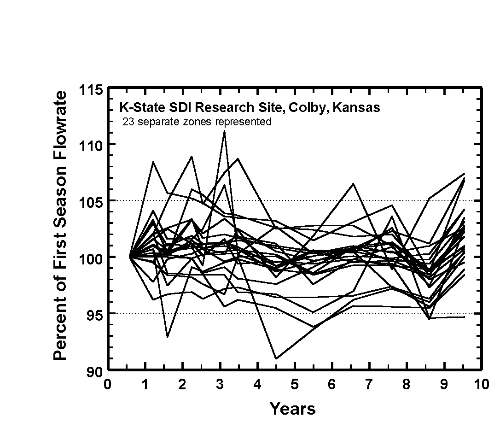

SDI system life must be at least 10-15 years to reasonably approach economic competiveness with full sized center pivot sprinkler systems that typically last 20 years (Figure 4). Using careful and consistent maintenance, a 15-20 year SDI system life appears obtainable when high quality water from the Ogallala aquifer is used. The system performance of the K-State SDI research plots has been monitored annually since 1989. Pressures and flowrates for each zone have been measured at the end of each irrigation season to allow comparisons of long term flowrate degradation. The time series representation of a study area (23 separate zones) at Colby, Kansas indicates that in the vast majority of cases, flowrates did not vary over +/- 3% over the 10 seasons (Figure 5). In fact, flowrates at the close of 1998 were predominately 0-3% higher than in 1989. This study area has received shock chlorination approximately 2-3 times each season, but has not received any other chemical amendments such as acid or fertilizer. The water source at this site has a TDS of 279, hardness of 189.1, and pH of 7.8. This water source would be a moderate chemical plugging hazard according to traditional classifications. It is possible that the depth of the SDI system (16-18 inches) has reduced the chemical plugging hazards due to less temperature fluctuations and negligible evaporation directly from the dripline.

Figure 5. Variation in zone flowrate for 23 separate zones during the 10 year period from 1989 to 1998 at K-State SDI research site, Colby, Kansas.

Concluding Statements

Research progress has been steady since 1989. Irrigators are watching the results of K-State closely. Some irrigators have begun to experiment with the technology and most appear happy with the results they are obtaining. The authors hope that by K-State developing a knowledge base in advance of the irrigator adoption phase that the misapplication of SDI technology and overall system failures can be minimized. Economics of the typical Great Plains row crops will not allow frequent system replacement or major renovations. Irrigators must carefully monitor and maintain the SDI system to assure a long system life.

Continued or new areas of research are concentrating on optimizing allocations of water, seed, and nutrients, utilizing livestock wastewater, developing preliminary information about SDI use with other crops besides corn, water and chemical application uniformity, and finally system design characteristics and economics with a view towards system longevity.

For further information contact:

Dr. Freddie R.. Lamm, Research Agricultural Engineer

KSU Northwest Research-Extension Center

105 Experiment Farm Road., Colby, Kansas 67701-1697

Phone: 785-462-6281

Fax: 785-462-2315

Email: flamm@ksu.edu

SDI Website: http://www.ksre.ksu.edu/sdi

This paper was first presented at the Irrigation Association International Technical Conference and exposition, Orlando, Florida, November 10-12, 1999.